Motivation

Building a product involves many steps before released to the public. Prototyping allows designers to iteratively test their product designs, measurements and usability, and allows marketers to collect valuable stakeholder and user feedback.

With the advent of 3D Printing and CAD technology, prototyping has become more efficient and flexible. A subset of Rapid Prototyping (RP) techniques, which involves CAD models being 3D printed to yield short iteration times, has proven to greatly improve prototyping efficiency. However, despite these innovations, design prototypes can still be costly and inefficient. Furthermore, “smart” devices result in an increasing number of upcoming devices that involve software components that are hard to integrate into a prototype.

Competitive Analysis

We compare the PrototypeVR with 3D printing, physical prototyping and AR prototyping methods to identify the privileges and limitations of these prototype methods, which hopefully helps us revise existing functions and explore the potential features needed to improve PrototypeVR.

Finding:

We analyzed the functions, tools, effects, advantages and disadvantages of several prototype method and found that using VR for prototype has great advantage in time and money cost. However, there are considerable user barrier for users' skillset and hardware equipment. VR testing has certain limitations, but it is sufficient for most daily product testing.

Physical prototypes are expensive but have the widest applications. AR prototype is the most balanced tool. Therefore, it is critical to find the applicable scenarios for PrototypeVR products.

Objective

We aim to design and develop PrototypeVR to provide a high-efficiency rapid prototyping workflow that allows users to simulate a full operation test combining 3D model and 2D screen transitions in VR. Based on literature and market research, we expect to make up for the lack of applicability by diving into physical functions and 2D rapid prototyping in the product.

Physical Embedment

Multi-mode Combined

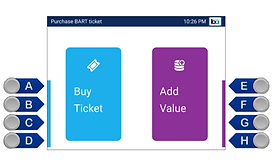

User flow

To demonstrate the workflow of using this product in VR, we used the redesigned ticketing system of the ticketing machine in subway stations as an example.

Step1

Design 3D models and 2D interactive prototypes separately and synchronously.

Step2

Export model with FBX file and prototype to PNG file and JSON data.

Step3

Test all-encompassing aspects of products in VR

Function Mode

Future plan

Target User

Considering the high hardware requirement, we will target at professionals and student with lab access at this time.

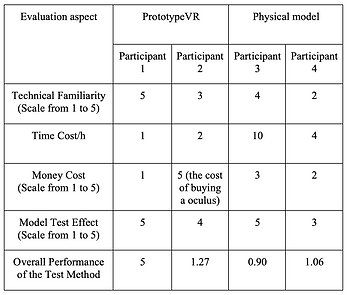

Evalution Test

We put the test audience into two groups. One group used PrototypeVR for testing and the other made handmade physical models instead. We invited each participant to conduct a low-fi prototype test, record the time and any difficulties they had during the test. After they finish the experiment, we then asked them to fill a post-test survey to rate the ease of use, test effect and money efficiency from 1 (low) to 5 (high). Results are what is shown in the right:

According to conclusion in competitive analysis, PrototypeVR provides higher fidelity, time efficiency and cost efficiency, which contribute to the improved test performance. Aim to quantitatively calculate the efficiency of product testing under the same time and money cost unit, we estimate the final performance using the formula:

Where E is the mean of model test effect, m is the mean of money cost and t is the mean of time cost. Each participant gets 5, 1.27, 0.90, 1.06 respectively. We hypothesize that PrototypeVR provides a better test effect than the physical handmade prototype. Also, we predict that PrototypeVR would save a lot of time when compared to other methods that achieve similar effects. However, PrototypeVR may not be applicable for people who don't own an Oculus device, which greatly increases the prototype cost and hinders accessibility.

Video

Future Work

Although we were able to build a working pipeline of creating prototypes in VR, there are many improvements that can be made.

1.One crucial next step would be conducting a semester-long in-person usability tests with at least 10 people to obtain actual data in the ease of use of the workflow and determine best applicable scenarios for users employing PrototypeVR rather than other prototype methods.

2.Improvements to the Figma plugin will also allow a more seamless user experience by exporting all the necessary files all at once rather than having to copy the JSON file and manually exporting the screen image files. Also, making the Unity plugin more accessible to people without Unity knowledge would be great as well; abstracting away and automating collider and script setups would be really helpful for people with less Unity experience and for speeding up the prototyping timeline.

3.We also hope to add the ability to quickly modify some of the properties of the 3D model such as the dimensions, tilt, and elevation. Therefore, should there be any last minute changes, those can be edited directly in Unity rather than going back to the CAD model itself. These changes would be primarily for improving the VR experience and helping it be more realistic rather than major changes to the 3D model.